PRODUCTION PROCESS

The main ingredients of fresh beer are 98 % Greek malt from barley or wheat, hops, yeast and water.

The main ingredients of fresh beer are 98 % Greek malt from barley or wheat, hops, yeast and water.

MILLING THE GRAIN

Beginning In the brew house, different types of malt are crushed together to break up the grain kernels in order to extract fermentable sugars to produce a milled product called grist.

Beginning In the brew house, different types of malt are crushed together to break up the grain kernels in order to extract fermentable sugars to produce a milled product called grist.

MASH CONVERSION

The grist is then transferred into a mash tun, where it is mixed with heated water in a process called mash conversion. The conversion process uses natural enzymes in the malt to break the malt’s starch down into sugars.

The grist is then transferred into a mash tun, where it is mixed with heated water in a process called mash conversion. The conversion process uses natural enzymes in the malt to break the malt’s starch down into sugars.

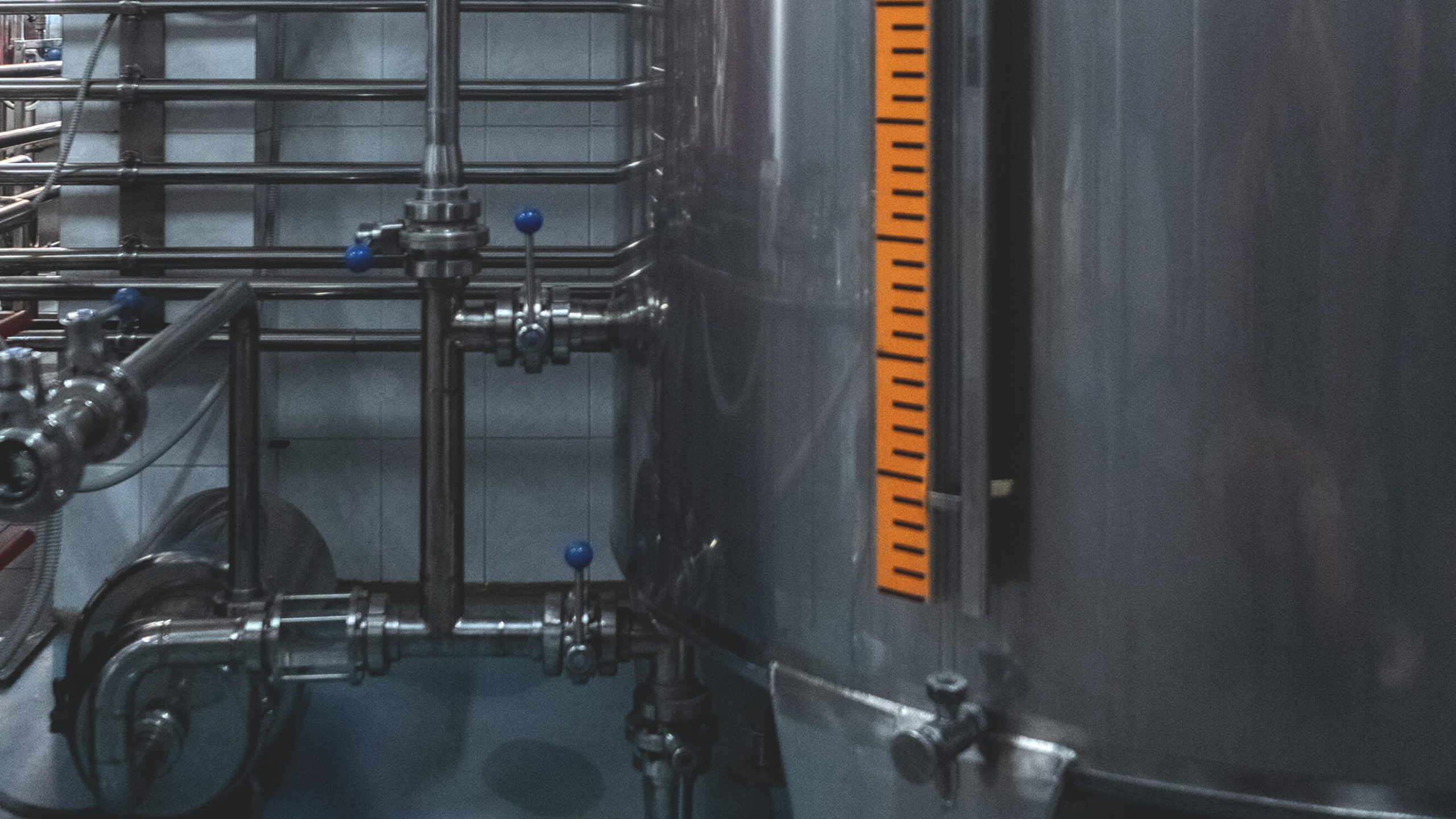

LAUTERING

The mash is then pumped into the lauter tun, where a sweet liquid (known as wort) is separated from the grain husks.

The mash is then pumped into the lauter tun, where a sweet liquid (known as wort) is separated from the grain husks.

THE BOIL

The wort is then collected in a vessel called a kettle, where it is brought to a controlled boil before the hops are added.

The wort is then collected in a vessel called a kettle, where it is brought to a controlled boil before the hops are added.

WORT SEPERATION AND COOLING

After boiling, the wort is transferred into a whirlpool for the wort separation stage. During this stage, any malt or hop particles are removed to leave a liquid that is ready to be cooled and fermented.

After boiling, the wort is transferred into a whirlpool for the wort separation stage. During this stage, any malt or hop particles are removed to leave a liquid that is ready to be cooled and fermented.

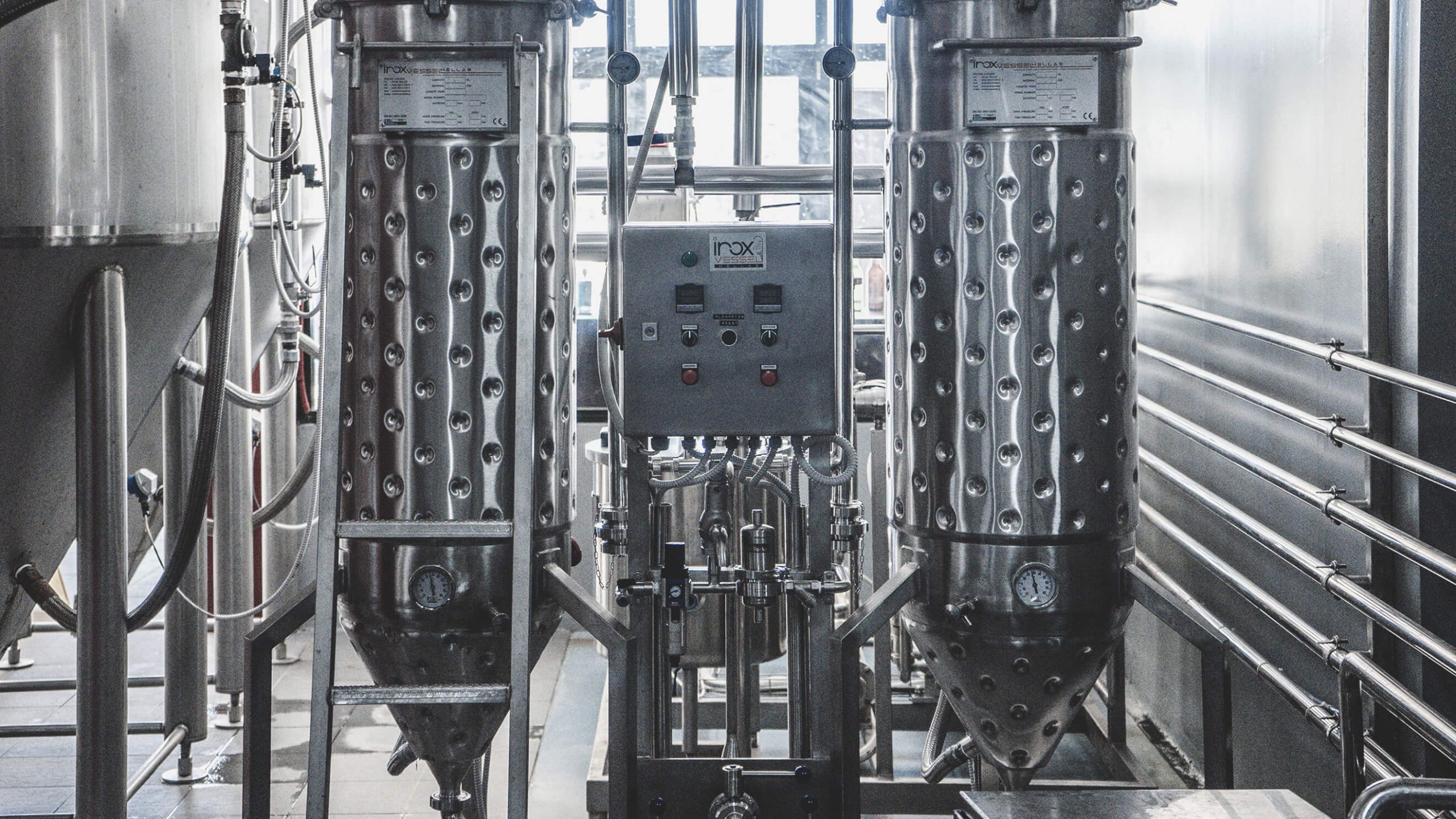

YEAST PROPAGATION

Υeast Propagation System for top and bottom fermented yeast.

Υeast Propagation System for top and bottom fermented yeast.

FERMENTATION

To start the fermentation, yeast is added during the filling of the vessel. Yeast converts the sugary wort into beer by producing alcohol, a wide range of flavors, and carbon dioxide (used later in the process to give the beer its sparkle). After fermentation, the young “green” beer needs to be matured in order to allow both a full development of flavors and a smooth finish.

To start the fermentation, yeast is added during the filling of the vessel. Yeast converts the sugary wort into beer by producing alcohol, a wide range of flavors, and carbon dioxide (used later in the process to give the beer its sparkle). After fermentation, the young “green” beer needs to be matured in order to allow both a full development of flavors and a smooth finish.

DIATOMIC EARTH FILTER

Through this the beer filtered and then transferred in BBT (Bright Beer Tank).

Through this the beer filtered and then transferred in BBT (Bright Beer Tank).

CARBONATION AND CELLARING

After the beer is filtered and carbonated. Transferred to the bright beer tank and the beer is ready to be packaged after bottling and kegging.

After the beer is filtered and carbonated. Transferred to the bright beer tank and the beer is ready to be packaged after bottling and kegging.

QUALITY CONTROL

Throughout the production process until the final product, continuous checks are carried out by the Quality Control Department of the brewery to ensure the quality of the product.

Throughout the production process until the final product, continuous checks are carried out by the Quality Control Department of the brewery to ensure the quality of the product.

BOTTLING

The product is available in 500 & 330 ml bottle and 20L, 30L & 50L barrels.

The product is available in 500 & 330 ml bottle and 20L, 30L & 50L barrels.

At all stages of production of fresh beer, Corfu Brewery holds up its environmental awareness with environmentally friendly techniques .

More specifically, the water used in the production is then watered with the same water.

The malt after its use is placed in special bags and donated to farmers of Corfu because it is valuable food for animals. Part of it becomes compost and is used as fertilizer.